TECHNOLOGIES

CONTINUOUS INVESTMENTS, A CHOICE AND A BELIEF

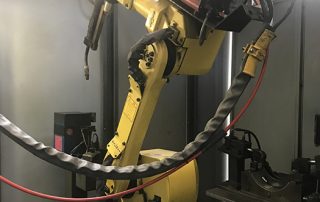

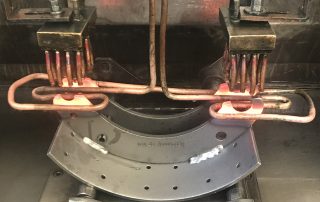

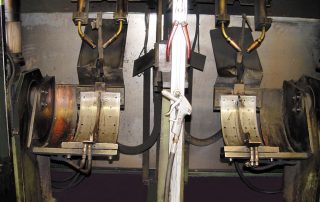

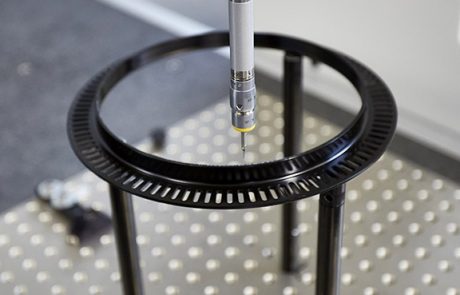

Our production department is equipped with more than 20 presses from 60 to 1600 tons capacity, 2 dedicated automated lines, CNC machines, welding machines, 6-axis welding robots, rolls bending machines, riveting machines, induction harden equipment, grinding & turning machines & shot-blasting equipment.

Such machinery allows us to manufacture a wide range of products, from small to big metal parts. We manage large and small volume productions with different raw materials.

The tools and equipment maintenance activities are performed in house by a suitable department that supports the stamping department.